Just-in-Time Manufacturing: A Comprehensive Guide

The manufacturing industry thrives on efficiency gains. Any opportunity to minimise waste and reduce your business costs means greater revenue, higher profits, and happier customers.

Just-in-time (JIT) manufacturing is a production management approach that helps you lift efficiency and streamline your operational processes.

What is Just-in-Time Manufacturing?

Just-in-time manufacturing is a strategy that directly aligns raw-material supply deliveries with production schedules to increase efficiency and decrease waste. This system requires accurate demand forecasting and involves receiving goods only as they are needed in the production process.

Implementing JIT in manufacturing operations can significantly reduce lead times and inventory levels, leading to cost savings and more responsive production cycles. It's particularly beneficial for companies looking to minimise storage space and reduce capital tied up in unsold stock.

Key Features of JIT

JIT systems are built on several core principles that enable lean and efficient operations:

- Demand-Driven Production:

Manufacturing or ordering is triggered by actual customer demand rather than speculative forecasts. - Lean Inventory Management:

Stock levels are kept to the absolute minimum required to fulfil current orders. - Supplier Integration:

Strong relationships with suppliers ensure the timely delivery of materials in smaller, more frequent batches. - Continuous Improvement:

JIT requires ongoing refinement of processes to maintain efficiency and responsiveness. - Pull System:

Production operates on a pull basis, meaning goods are produced only when there is demand, avoiding overproduction.

Advantages of JIT

JIT manufacturing aligns material orders with production schedules, ensuring goods only arrive as needed for the manufacturing process.

Ultimately, the success of JIT manufacturing hinges on the seamless integration of supply chains, quality control, and accurate demand forecasting.

When implemented effectively, JIT can lead to a more responsive and efficient production system, but it requires a commitment to continuous improvement and problem-solving to address the inherent risks and challenges of this approach.

Advantages of JIT manufacturing include:

- Reduced storage and financing costs

- Shorter production lead times

- Less waste

- No overproduction

- Greater resource efficiency

- Better cash flow

- Shorter throughput times

- Increased responsiveness to market changes

One of the main benefits of just-in-time manufacturing is the reduction of inventory levels, which helps manufacturers avoid excess costs associated with storage and inventory management. By producing goods only as they are needed, companies can minimise the amount of capital tied up in unsold products and lower the risk of inventory obsolescence.

JIT also contributes to improved quality management, as the production process becomes more streamlined and responsive to immediate demand. This can lead to shorter lead times, quicker turnaround on orders, and increased customer satisfaction. Additionally, JIT can result in lower labour costs due to the elimination of unnecessary handling and storage of materials.

Implementing JIT can significantly improve efficiency and reduce waste. However, it requires a long-term commitment to creating an environment that prioritises flexibility, efficiency, and strict quality control.

This can be particularly beneficial in industries such as craft beer, craft distilleries, supplements, and food manufacturing, where consumer preferences can change rapidly, and products often have limited shelf lives.

Here are some examples:

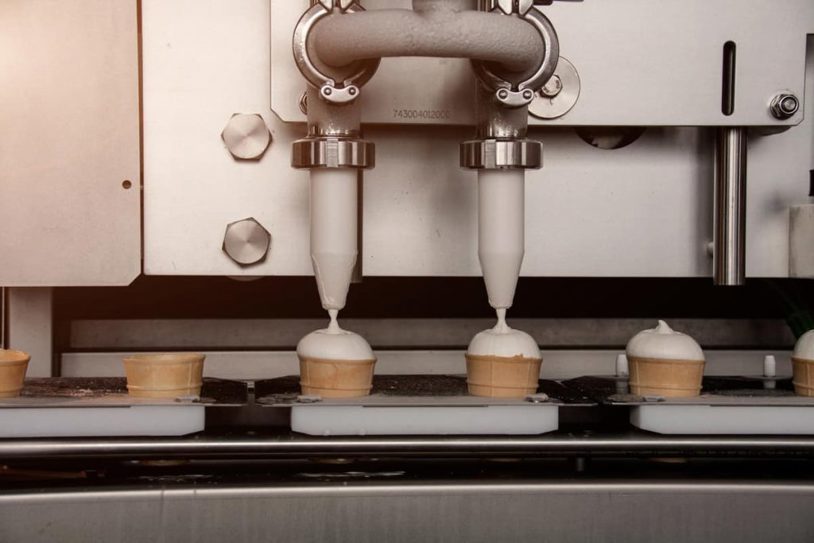

- In the context of food manufacturing, an effective just-in-time production strategy means ordering ingredients in precise quantities based on real-time demand, thus minimising waste and ensuring freshness. JIT demands meticulous planning, a culture of continuous improvement, and responsiveness to meet the dynamic needs of the food market.

- For a craft beer manufacturer, JIT could involve closely monitoring sales trends and customer feedback to predict demand more accurately. This would allow the brewery to produce beer in quantities that meet current demand without overproducing, thus reducing the risk of spoilage and excess inventory.

- In a craft distillery, they might use JIT to manage the production of spirits, ensuring that each batch is distilled based on actual orders rather than speculative forecasting. This helps in maintaining the freshness of the product and reducing storage costs.

- In the supplements industry, where products are sensitive to expiration dates, JIT can help in managing the procurement of raw materials and the production of supplements so that they are made to order, ensuring maximum potency, and minimising the risk of having unsold stock that goes out of date.

- For lighting manufacturers, JIT can streamline the production process by synchronising the assembly line with real-time sales data, thus avoiding overproduction and enabling quicker response to market trends, such as the rise in demand for energy-efficient LED lighting.

Disadvantages of JIT

The main disadvantages of just-in-time manufacturing include the risk of running out of stock caused by the system's reliance on accurate demand forecasts. If these forecasts are incorrect, a manufacturer may not have enough inventory to meet consumer needs.

Disadvantages of JIT manufacturing include:

- A dependency on accurate demand forecasts

- Vulnerability to supply chain disruptions

- Potential for increased stress on workers due to the need for precision timing

JIT systems also have little room for error or unexpected demand surges, as they maintain minimal inventory levels. This can lead to production bottlenecks if suppliers experience delays or disruptions.

Additionally, the minimised inventory holding in JIT can result in quality control issues, as there is less opportunity to inspect goods over time. Implementing JIT requires a robust and responsive supply chain, which can be a significant challenge for some businesses.

The balance between the advantages and disadvantages of just-in-time manufacturing must be carefully managed to ensure that the system delivers on its promise of increased efficiency and reduced waste.

Consider the advantages and disadvantages of JIT manufacturing to make an informed decision about whether it's right for you.

Real-World Examples of JIT

Toyota

Toyota is often considered to be the guru on lean manufacturing, as they were one of the first notable names to adopt the Japanese philosophy of Kaizen in their business model. Kaizen first came about after World War Two and directly translated, it means improvement.

In business, it is widely used to denote continuous improvement with lean manufacturing and waste reduction as two of its core processes. Toyota championed this structure of lean manufacturing using JIT, and as a result, many companies have experienced success since. A real-world example, Toyota experienced in 1997, goes like this: Toyota had streamlined their JIT business model since its first adoption in the 1970s and after 15 years, it was truly optimised in every sense.

However, in February 1997, a manufacturer they used for brake valves experienced a devastating fire, which eradicated all stock and rendered them unable to supply Toyota. The manufacturing giant had to scramble to find an alternative supplier in the two days after, however, shutting down supply for two days cost them $15 billion and 70,000 cars. Though this sounds horrific, it could have been significantly worse.

Dell

Dell has used JIT inventory to establish themselves as a computing business which carries minimal stock and instead uses short lead times to manufacture or assemble components as and when required. The way they have achieved this is by building strong, dependable relationships with their own suppliers, where they have negotiated for them to carry the stock rather than Dell.

This means lead times can remain short, and they have relinquished the responsibility and associated risks of carrying stock that does not have a purpose.

McDonald's

In the food and beverage industry, it makes sense to implement a JIT inventory system, as finished products for human consumption have a lifespan beyond which they are worthless.

McDonald's shows us what this system looks like in the real world, where they have components onsite for the immediate future, although nothing is assembled or made until a customer places an order.

This ensures that when a customer places an order, the product is assembled in exactly the same way every time with exactly the same experience being offered.

Apple

The tech giant, Apple, has made giant steps in the direction of lean manufacturing and JIT inventory. Their motivation was not just reducing waste and associated costs but also to reduce energy consumption, ensure the energy they did consume was absolutely necessary while being renewable, and with the notion of improving their green production by partnering with the WWF and other supply chain leaders who are instrumental in China’s green transformation.

So how did they do it?

They established reliable and trustworthy relationships with their suppliers so that they could indeed order stock with far shorter lead times with the assurance orders would be met. They also recognised the value of dropshipping where products are shipped directly from the manufacturer to the customer, cutting out ‘middlemen’ and thereby reducing shipping and storage costs.

To fill Apple’s very large shoes, it requires a hard look at what you are doing and your current inventory management status. Apple recognised that their products generally have approximately a year’s lifespan, depreciating in value by 1-2% every week. Therefore, there really was no point in retaining excess raw components which, although not consumable, have a notable short life span.

So, they made massive ground in tidying up their supply chain to match these constraints, were able to shut 10 of their 19 warehouses in the US and as a result, boast a days-to-inventory value of 3.2 days. Impressive indeed!

How to Implement JIT

Implementing an effective just-in-time production strategy in manufacturing requires a comprehensive approach that encompasses several key steps and principles. The core idea of JIT is to align production schedules closely with market demand, thereby minimising inventory levels and reducing waste.

Key considerations when implementing JIT:

- Understanding the demand forecasts

- Ensuring your production capacity meets product demand

- Building strong, mutually beneficial relationships with reliable suppliers

- Have steady production and high-quality workmanship

- Maintaining glitch-free plant machinery and equipment

- Empowering a culture that embraces continuous improvement

The implementation of JIT across these industries requires a thorough assessment of your current manufacturing processes to identify areas of waste and inefficiency. This may involve analysing production cycles, inventory levels, and supplier relationships.

Here’s how to implement just-in-time manufacturing in six steps.

1. Get your staff involved in the process

It's crucial to involve your workforce in the transition to JIT because their cooperation and understanding are essential for the success of this strategy. Investing in cross-training your employees is beneficial, it increases the flexibility of your workforce, allowing staff to perform multiple tasks and adapt to changing production needs.

2. Build healthy supplier relationships

Establishing strong, mutually beneficial relationships with suppliers is also key, as successful JIT manufacturing depends on its ability to deliver smaller batches of materials more precisely and frequently when needed.

3. Implement real-time inventory tracking

A robust inventory management system is also critical, as traditional methods may not support the dynamic nature of JIT. Implementing a pull system, where production is driven by customer demand rather than forecasts, is a fundamental aspect of JIT.

4. Improve production processes

Streamlining the production layout to reduce movement and handling can also contribute to greater JIT efficiency. Minimising unnecessary movement and handling aligns with lean manufacturing principles, which focus on eliminating non-value-added activities and ensuring that every step in the production process adds value to the final product.

5. Factory layout optimisation

A well-organised production design facilitates better inventory management, reduces the risk of damage to materials and products, and can improve worker safety by reducing clutter and potential hazards.

6. Keep getting better

Continuous improvement, a principle of Kaizen, is integral to JIT, as it involves consistently refining processes to enhance quality and efficiency. This continuous cycle of evaluation and improvement helps you to maintain a competitive edge.

Just-in-time manufacturing systems

Just-in-time manufacturing systems have been adopted by various industries and work by producing goods in small batches and only when they are needed.

This means there is little or no excess inventory, leading to substantial cost savings on storage and handling, smaller investments in inventory stock, and elimination of waste due to unsold or spoiled goods.

The evolution of JIT continues as companies strive to refine their processes and respond to the dynamic demands of the global market. Advancements in technology and strategy are reshaping JIT manufacturing, making it more efficient and responsive to the dynamic market conditions.

Manufacturing inventory management software is an essential tool for implementing JIT manufacturing. It helps you accurately forecast demand, optimise stock levels, and reduce waste.

Next Steps

So, given these examples, what would be your next steps in instigating a JIT approach to your inventory management? To know where to reduce wastage and make informed decisions around ordering to meet demand, you need to have accurate data in front of you, both in real-time and from which you can make predictions.

For this, inventory management software such as Unleashed is priceless. Without accurate data, implementing JIT can be challenging and may lead to inefficiencies. Inventory management software like Unleashed provides the real-time insights you need to succeed

Start your 14-day free trial today and see what Unleashed inventory management can do for you.

Frequently Asked Questions

What skills are needed for JIT?

To successfully implement just-in-time manufacturing, you’ll need the following skills:

-

Demand Forecasting – Ability to predict customer demand accurately.

-

Inventory Management – Skills in maintaining lean stock levels and using real-time tracking systems.

-

Supplier Relationship Management – Building strong, reliable partnerships for timely deliveries.

-

Process Optimisation – Knowledge of lean principles and continuous improvement (Kaizen).

-

Cross-Functional Collaboration – Effective communication between procurement, production, and logistics teams.

-

Problem-Solving & Adaptability – Quickly addressing disruptions and adjusting processes.

What are the key principles of JIT?

The core principles of JIT include:

-

Demand-Driven Production – Manufacture based on actual customer demand, not forecasts.

-

Lean Inventory Management – Keep stock to the minimum required for current orders.

-

Supplier Integration – Strong supplier relationships for frequent, smaller deliveries.

-

Continuous Improvement (Kaizen) – Ongoing refinement of processes for efficiency.

-

Pull System – Production triggered by demand rather than pushing goods into the market.

Do Coca-Cola use JIT?

Yes, Coca-Cola uses JIT in their supply chain. They operate a demand-driven production system to ensure freshness and reduce waste. Coca-Cola uses real-time data and strong supplier networks to maintain lean inventory and respond quickly to market changes.

Is JIT still relevant today?

Yes, JIT remains highly relevant in today’s manufacturing and supply chain environments because it helps businesses reduce waste, lower costs, and improve sustainability.

Modern technologies such as real-time data analytics, automation, and advanced inventory management systems have made JIT even more efficient and adaptable. Its ability to support adaptability in changing markets, where consumer demand changes rapidly, ensures that industries like automotive, technology, food, and e-commerce continue to rely on JIT for competitive advantage.