In the manufacturing industry, a bill of materials (BOM) functions as a recipe or instruction manual for completing an assembly. It’s like a cheat sheet for building products. BOMs ensure all the right parts and materials are used for each assembly and they reflect the relationship between raw materials and finished goods.

This bill of materials guide will help you understand what a BOM is and the benefits of using one in a manufacturing operation. We’ll also cover how a bill of materials works, the different types of BOM, and tips for making BOMs easier to manage.

Key takeaways

- A Bill of Materials (BOM) is a detailed document listing all parts, materials, and instructions needed to manufacture a product, ensuring accuracy and efficiency in production.

- BOMs are critical for managing production costs, streamlining inventory, and reducing errors, making them essential for effective manufacturing and supply chain management.

- There are different types of BOMs, such as single-level and multi-level, which cater to various product complexities and manufacturing processes.

What is a bill of materials?

A bill of materials (BOM) is a record of all the parts, materials, and processes required to manufacture a product. A BOM functions as a hierarchical list detailing how a product is built. It displays the exact quantities of components required for each level of the assembly, from raw materials such as fastenings to sub-assemblies and packing materials.

How have BOMs evolved?

As technology has evolved, so have BOMs. Previously, they were manual records, either depicted through a drawn diagram or on a spreadsheet. In the 1960s, BOMs became more notable and with the increase of computers in the 70s/80s, they started to be incorporated with broader systems, allowing BOMs to be integrated with inventory management solutions.

Multi-level bill of materials

A bill of materials can cover the smallest of assemblies to large machinery and equipment builds.

They may be simple documents or contain complex, multi-levelled descriptions of a product comprised of many sub-assemblies. Multi-levelled bills of materials can consist of several smaller BOMs that each build one component from the final assembly.

You can use BOMs as a pick list of all items issued in production. When documented correctly, they serve as a helpful tool for costing finished products.

BOM meaning in manufacturing

In manufacturing, a BOM describes the individual components used in production and the relationship between each of those individual parts. BOMs are beneficial in numerous ways to manufacturers. At their core, they solve problems in efficiency, waste, and cost.

Also known as a manufacturing bill of materials (MBOM), BOMs in manufacturing can include details of the tools and equipment required for assembly or sub-assembly and any other consumables needed for the manufacture of a final shippable product.

Bill of materials example

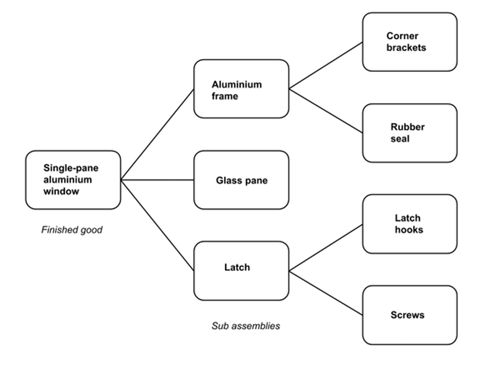

A bill of materials is hierarchical in nature.

The finished product ranks at the primary level with subassemblies, components, and other parts at lower levels of importance. For example, a single-pane aluminium window sits at the highest level while subassemblies and other modules are listed in subsequent levels:

An itemised bill of materials would include every aspect of the window assembly down to packaging and even the safety sticker for the glass pane.

Which industries use a BOM?

A Bill of Materials is crucial in industries like manufacturing, electronics, automotive, and aerospace.

It specifies every component, material, and part needed to assemble a product, along with assembly instructions.

In these industries, BOMs ensure accurate inventory management, cost control, and efficient production processes. For example, in electronics, a BOM lists all the resistors, capacitors, and semiconductors required to build a circuit board, while in automotive, it includes all parts necessary for vehicle assembly.

This ensures that all materials are available and that production runs smoothly.

Benefits of an effective bill of materials in manufacturing

Bills of materials are essential tools for eliminating problems in any company that runs lean and continuous improvement processes. The three core benefits of BOMs for manufacturers are more efficiency, less waste, and lower costs. Here’s how they achieve them.

1. Boost operational efficiency

The primary benefit of a bill of material is that it identifies all the inventory stock, including raw materials, subassemblies, components, and parts necessary to create a single finished product. This ensures more efficient inventory control as all the quantities required for an assembly can be correctly ordered.

2. Improve visibility and reduce waste

You can use a BOM to sport and cut out unnecessary waste. They provide businesses with a complete and accurate picture of the inventory stock and processes associated with creating a single product.

By utilising this knowledge of every component and step in the manufacturing process, operations teams can make proper trade-offs between time, cash flow, and inventory control throughout the life of a product.

Bills of materials also help to reduce errors such as ordering the wrong part or the wrong quantities or similar issues that can lead to costly downtime and production delays.

3. Manage production costs

The BOM helps to identify the basic cost of components which, once component costs are known, businesses identify if it is more cost-effective to outsource or purchase assemblies externally than to manufacture internally.

You can input BOM data into your inventory management software to boost efficiency. They make manufacturing processes more cost-effective and aid decision-making.

An all-inclusive measure of total assembly promotes informed decision-making and highlights areas for improved efficiency, quality enhancement, and improved cost-effectiveness.

For companies that outsource manufacturing activities, having an accurate bill of materials is particularly important. A BOM for contract suppliers should be complete, accurate and reviewed at regular intervals to avoid cost blowouts and production delays.

What’s included in the bill of materials

A bill of materials structure should include everything required to produce a final product. This includes information about all the raw materials, sub-assemblies, and parts needed to build the product.

What you’ll typically find included in a bill of materials:

- Quantity– the number of parts to be procured or manufactured should be specified for each assembly. Quantity is a primary requirement of any BOM.

- Unit of measurement – to ensure that exact quantities are ordered a BOM should specify the unit of measure for each quantity. For example, per unit, lengths, litres, inches, grams, kilograms, square feet, or cubic feet.

- BOM level – the BOM level specifies the number or ranking for each part to help identify all the elements of the BOM, whether single or multi-level.

- SKU – a stock-keeping unit (SKU) is assigned to each item for easy reference and effortless tracking of each part.

- Part name – the unique name of each item combined with a specific part number helps to identify the item easily and effectively.

- Raw material – the BOM should specify the exact quality or type of essential raw material required in the manufacturing process to produce a finished product.

- Description – each part should have a suitable description of the part to help distinguish it from similar parts.

- Notes – the notes simply provide any additional information relevant to the BOM save for the description of parts.

- Images – having images or diagrams of the product being produced provides a visual representation to help easily understand each component and cross-reference the BOM details with the image.

- Procurement method – this identifies whether the required part or inventory is purchased externally or manufactured internally.

- Vendor name – if the part is not manufactured internally, the BOM should include at least the name of the company that can supply it.

You can also include detailed instructions, diagrams, and links to external fines to support the manufacturing process. What the bill of materials does not usually include are the prices of each component used to make up an assembly or finished good.

How a bill of materials works

Bill of materials are hierarchical documents that detail how an assembly should be built. In manufacturing, they’re used to ensure goods are produced correctly and to track the quantity of components consumed in each assembly.

There are multiple BOM structures and ways to display a bill of materials. The option you choose will depend on your task – and the requirements of the item being assembled.

First, let’s look at how basic single-level BOMs work.

Single-level bill of materials

A single-level bill of materials represents one level of an assembly.

This type of BOM is mostly used to build products that are simple to build, without requiring any other components to be manufactured.

Multi-level bill of materials

A multi-level BOM, sometimes called an indented bill of materials, details how you build a finished good – including all the sub-assemblies, components, and materials that go into it.

The hierarchical structure of a multi-level bill of materials maps out all the elements you’ll need to create a product. Multi-level BOMs display the finished product at the top and then break down the components that go into that product. This can include SKUs, part descriptions, quantities, costs, and other relevant specifications.

Multi-level BOMs are vital in manufacturing, especially for manufacturers who use multiple sub-assemblies (several components constructed to make a single unit that is used as a part of a larger assembly) to produce their finished goods.

Planning bill of materials

A planning bill of materials, also known as a modular BOM, is a bill of materials that’s produced for the purpose of planning future production requirements.

You can used planning BOMs for demand forecasting by identifying what future products might require. This enables businesses to make smarter decisions around purchasing and sales processes.

When companies need to predict their capacity to produce goods, planning BOMS can play a vital role in ensuring an accurate prediction.

Bill of materials displays

Bill of materials can display information in two directions:

- BOM explosion: This type of BOM display demonstrates how an assembly is broken down into its individual components and parts, from the highest level down to the lowest levels. It helps manufacturers see what is required to construct a final product.

- BOM implosion: An imploded BOM is the opposite of an exploded BOM. It reflects where lower-level parts or raw materials are used and the range of assemblies, sub-assemblies, and products they can be used for.

Consider the bill of materials for a bicycle.

One could decompose a bicycle's bill of materials to display the handlebar, wheels, seat, chassis, chain, and pedals. And most of those parts could then be exploded again – for example, a wheel BOM can explode into the tire, hub, spokes, and fastenings that comprise it.

Alternatively, you could streamline the requirements of the tire, hub, spokes, and fastenings into a BOM for the wheel, which can be imploded into the requirements of the bill of materials for our bicycle.

In this way, the true capacity and requirements of products and materials can be better understood by manufacturers.

How to create a bill of materials

You can create a bill of materials manually, using a spreadsheet or paper-based system, or automatically, using bill of materials software. Below we explain how to build a BOM using either system.

How to create a bill of materials using BOM software

The most efficient and accurate way of creating a BOM is to use bill of materials software. Bill of materials software streamlines the process of building assemblies and sub-assemblies by automatically informing you what quantities are required, where to find them, and whether they’re available.

The benefits of creating BOMs with bill of materials software include:

- Efficient production planning: You can use BOM software to remove guesswork from production and get a clear view of what you’re able to produce. This limits bottlenecks and helps improve the accuracy of your production planning process.

- Improved production efficiency: You can calculate the goods required for a production by multiplying the quantity of each SKU in a BOM required by the number of completed assemblies needed, minus any parts or components already held in stock. Inventory software automates this complex task, reducing your admin time and ensuring accurate calculations.

- Centralised data: Having a single source of truth for your BOMs is critical. A cloud-based bill of materials system gives you one reliable place to manage your documents and sync your inventory with what’s needed for production.

- Demand-driven purchasing: Bill of materials software enables you to start the production planning and purchasing process from within a sales order, helping you achieve an efficient Just-in-Time approach to your manufacturing.

- Fewer production costs, wider profit margins: A crucial benefit of bill of materials software is that it helps you avoid dead stock or stockouts. The money saved from holding less excess inventory and experiencing fewer bottlenecks instantly improves profitability.

In the video below you can see how to create a bill of materials using Unleashed BOM software by first designating different elements as either ‘assembled’ or ‘component’ products.

How to create a bill of materials in Excel

Online inventory control software is the most effective way of creating and working with bills of material. However, if you're a business that's working with spreadsheets, here’s how to create a simple bill of materials in Excel:

- Create a new landscape-orientated workbook in Excel. On the first page list all your main products and or projects including any subassemblies. The product number will reference the corresponding product bill of material that lists the BOM in detail. Remember to always record the revision number and date of your product or project.

- Add column headings for your bill of materials. Headings should reflect all aspects of a part relevant to the completed project such as Part Number, Name, Description, Quantity, Units and Unit Cost.

- Format your columns. For example for unit costs, you can click the $ symbol on the menu bar to format the currency. Then select ‘Save As’ and save the workbook as an Excel template so that you can use and adapt it to create a BOM for a variety of products.

- For each new BOM, enter the details for each part in the rows under the headings. Include as much relevant information as possible, listing the manufacturer’s part numbers to ensure every part number is unique and to avoid confusion.

- Put a system in place to track all changes to the document. This can be a record of all previous versions and revisions, the changes made, by whom, and when. Ensure that each version is clearly marked and that the most recent one is always being used.

An example of what a bill of materials looks like in Excel

An example of what a bill of materials looks like in Excel

The main challenge when using Excel for your BOMs is that spreadsheets are plagued with issues and need to be constantly updated manually.

Once the file has been copied, saved to a desktop, or even emailed, the spreadsheet can be easily modified. It then becomes difficult to know with any certainty whether you’re using the latest, most accurate revision.

Types of bill of materials

BOMs can be implemented into practically any business in any industry. In food manufacturing, for example, bills of materials are used as literal recipes for creating food products.

- Try for free: Food Traceability Software

Let’s look at some of the common types of BOM and how they can be utilised.

Assembly bill of materials

An assembly bill of materials identifies the items and resources needed to assemble a parent item. Unlike a production bill of materials, the assembly BOM simply contains a list of sub-components without any necessary machines or work centres related to the build.

You can easily replenish any item with an assembly BOM by generating an assembly order directly from a sales order. When customers request a slight variance of an item, the assembly order has the flexibility to be modified on a per-sales order basis.

Engineering bill of materials (EBOM)

An EBOM is a special type of bill of materials that deals specifically with how a product is designed. It contains the list of all the equipment, parts, components, subassemblies, and assemblies that go into an engineering product.

Engineers typically create an EBOM using computer-aided design that provides the product design for more than one component, where necessary. Because the information contained in an EBOM is passed on to manufacturing, accurate parts and quantities must be given.

This information helps manufacturing operations make better purchasing decisions and avoid delays due to missing parts. It ensures the availability of everything necessary to consistently produce a quality product.

Manufacturing bill of materials (MBOM)

A manufacturing bill of materials describes the individual components used in the production of a finished good and it details the relationship between each of the separate parts used.

In manufacturing, all components required to manufacture a complete, shippable item are listed by part number, description, and quantity. An MBOM should include details of the tools and equipment required for assembly, sub-assembly and any consumables needed in the manufacture of the final shippable product.

Sales bill of materials (SBOM)

SBOMs represent an assembled finished good at the sales stage. The components for an SBOM must be sales items. Thus, the finished product is managed as a sales item rather than an inventory stock item.

The components can also be sales and inventory stock items.

For example, the finished product may be a set of outdoor furniture. With this BOM, both the finished product and the components appear as separate items on the sales order document. When you create the delivery to dispatch the customer’s order, the components listed in the BOM are deducted from raw inventory stock.

Configurable bill of materials (CBOM)

A CBOM is used by industries that have configured products. The creation of a CBOM is dependent on having a modular BOM structure in place because it is used to create customised versions of the products sold.

The benefit of a CBOM is that it reduces the effort required to maintain product forms. A CBOM is often driven by configurator software.

Service bill of materials

A service BOM is a list of all the serviceable parts needed to maintain an operational asset and applies to people servicing and maintaining machinery and equipment. A service BOM establishes a foundation for accurate, assessable information and provides relevant information to service-specific roles.

A service bill of materials should incorporate all information required to undertake a service job. The service BOM will be regularly updated along with a single master BOM to integrate the new engineering or product change orders.

Optimising bill of materials: Best practices

A simple BOM has several basic features such as part number, component description, quantity, and unit of measure. Others go into greater depth to utilise other product attributes. Whatever the complexity of your BOM, the best practices below provide guidance towards building and managing an effective BOM.

1. Tailor the BOM to project needs

Before creating a BOM, decide on the important details that are required from it and design the BOM to meet those requirements. Customise the BOM to the unique demands of your project or build.

2. Include sufficient detail

Include as much helpful information as possible to ensure the BOM is as clear, detailed, and accurate as possible. While some types of information aren’t always helpful, a general rule of thumb is the more detail, the better.

3. Check the details

Review the BOM carefully to make sure all necessary information is included and accurate before you upload or share it. Even small mistakes can be costly so review the details to ensure the information is correct.

4. Restrict access

Limit the number of people with editing access to the BOM, and allow editing access only where necessary. Other members of the organisation can still access and use the information but will not be able to make changes. This helps to protect against human error.

5. Implement a bills of materials software system

The most efficient way to effectively create and manage bills of materials is to implement an online bill of materials software system. Tools like Unleashed can help you get the most out of your bill of materials by streamlining processes and using automation to ensure the most current and up-to-date information is included.

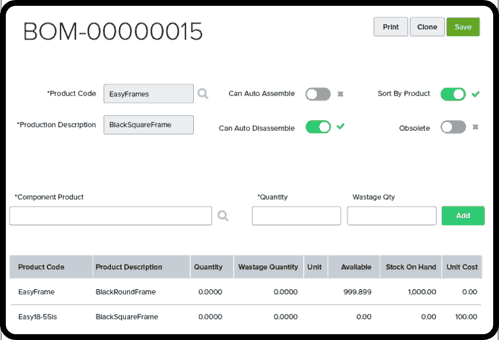

An example of how a bill of materials created using bill of materials software appears in the system.

An example of how a bill of materials created using bill of materials software appears in the system.

Bill of materials management

Bill of materials management refers to the process of inputting and managing the product data that’s critical to the production of a finished good. It involves recording all the information that goes into a bill of materials, including item quantities and specifications.

Effective BOM management contributes to greater manufacturing efficiency. When the right processes are in place to set up and manage bills of materials, your production lines will operate more smoothly with fewer bottlenecks.

Managing BOMs also requires a company to consider how and where they store their bill of materials documentation. This can mean controlling BOMs using bill of materials software, or simply managing the spreadsheet or filing cabinet where BOMs are kept.

More posts like this:

- How to Choose Bill of Materials Software

- Barcode System for Manufacturing: Benefits & How it Works

- Manufacturing Software: 15 Different Types & What They Do

Frequently Asked Questions

What is bill of materials?

Bill of materials (BOM) is a list of raw materials, sub-assemblies, components and quantities required to manufacture products, from start to finish. Bill of materials are required for calculating costs, accurate inventory management and methodical manufacturing processes.

What is an example of bill of materials?

If a beverage manufacturer has an order for 1,000 bottled apple juices. The BOM for this order would include all the ingredients to make the apple juice - consisting of apples, sugar, water, lemon juice, etc – the bottle, the lids and the labels.

How do you write a BOM?

To write a BOM, you need to include the name of each component, component number, component description, source, quantity per assembly, unit of measure for quality and any notes.

What is another name for the bill of materials?

Bill of materials can be known as ‘BOM’, ‘product structure’, ‘production recipe’, ‘assembly component list’ or ‘associated list’.

What is the difference between BOM and BOL?

A BOM is a list of all the components required to manufacture products. A BOL (Bill of Lading) is a legal requirement for logistics. This document works as a contract between the shipper and carriers, with receipts of transported goods.

What are the different types of BOM?

There’s a few different types of BOM, categorised by structure, lifecycle stage or specialised type.

Structure BOMs include single-level BOM (for simple products) and multi-level BOM (for complex products with sub-assemblies).

Lifecycle stage BOMs include engineering BOM (for a product’s design, including functional components, CAD details, etc), manufacturing BOM (for manufacturing-specific details), sales BOM (contains sales information, including product configuration) and service BOM (for after-sales support containing troubleshooting information)