Demand Forecasting: Benefits, Methods & Examples

Understanding and predicting customer demand is a vital part of inventory management, and helps businesses prevent stock-outs, maintain adequate inventory stock levels and increase overall profitability. It also has a major impact on cash flow and liquidity.

Overview

Demand forecasting is essential for managing inventory, improving cash flow, and meeting customer expectations.

This guide covers the key components of forecasting, from data analysis and collaboration to choosing the right method, and explores both qualitative and quantitative techniques, including regression analysis, machine learning, and the Delphi Method.

You'll also find practical examples using Unleashed’s Advanced Inventory Manager, tips to improve forecast accuracy, and a balanced look at the pros and cons of forecasting.

Whether you're refining your current approach or starting fresh, this article offers actionable insights to help you plan with confidence.

Table of Contents

- What is demand forecasting?

- Components of demand forecasting

- Advantages and disadvantages of demand forecasting

- What is demand planning?

- Why is demand forecasting important?

- Demand planning example

- Demand forecasting methods

- Demand forecasting software

- Demand forecasting best practices

- 6 highly useful demand forecasting tips

- Expert panel discussion

- FAQs

What is demand forecasting?

Demand forecasting is the process of estimating the number of products that customers will be willing to purchase in the future. It involves leveraging data and analytics about your product and the market to closely predict customer demand over a particular time frame.

- Discover: Demand planning and inventory forecasting software from Unleashed

- Learn more: The Best Inventory Management Software for Demand Forecasting

Components of demand forecasting

The main components of demand forecasting include data collection, analysis, collaboration and communication and selecting appropriate forecasting methods and techniques.

Data collection and analysis

Clean and reliable data must be collected, including market trends, historical sales data and influencing factors including seasonality, promotions and supply chain availability. Analyse this data to identify any patterns, trends and seasonal influences to understand past demand drivers.

Collaboration and communication

Insights found should be shared between departments – including sales, marketing and operations. Data could be shared with external partners, such as suppliers, ensuring all parties are aligned on changes.

Selecting the right forecasting method

Demand forecasting isn’t a one-size-fits-all; the right method can depend on a business's size and situation. Methods include:

- Delphi technique – A qualitative method requiring multiple rounds of surveys and feedback through a panel of experts to reach a consensus

- Regression analysis – A causal method to understand the relationship between demand and variables (prices and advertising costs)

- Machine learning – Uses complex data sets to identify patterns and makes accurate predictions through algorithms. Best for volatile markets.

Advantages and disadvantages of demand forecasting

Advantages of demand forecasting

Demand forecasting helps ensure supply meets demand while reducing waste. Through demand forecasting, businesses are better equipped to maintain stock levels, based on sales predictions and seasonal trends, reducing the possibility of stockout and overstocking.

By ensuring you’ve matched your inventory levels, customers will receive products exactly when they need them, and you’ll increase customer satisfaction.

Accurate forecasting also leads to better budgeting and cash flow because of the reduction in overstocking and stockouts.

Disadvantages of demand forecasting

Demand forecasting is only as accurate as the data it relies on, so using reliable sources is essential for accurate predictions. If your forecast is inaccurate, this can lead to a business over or understocking, increasing costs or missing sales opportunities.

One-off events or unforeseen disruptions can be difficult to account for, leading to a skew in the result.

What is demand planning?

Demand planning is demand forecasting put into action. Demand planning should work as an active part of your company’s resource planning system in order to forecast purchase and inventory requirements and respond to predicted customer buying habits. Done right, this will ensure inventory stock levels are optimised while meeting customer needs. Effective demand planning uses multiple data sources, such as:

- Historical sales data – using a two to five-year period is generally best practice for most systems in order to analyse sales activities and identify trends.

- Manufacturer forecasts – data from peers within your supply chain, e.g. manufacturers that you work with, can make for more accurate demand forecasts.

- Seasonal factors – most demand forecasts will account for seasonal variations in demand. Sales forecasts also consider other factors like special events – e.g. sports or cultural occasions – that can trigger peaks in sales.

- Constraints or business rules – does your business always purchase at certain levels to take advantage of a discount or reduce freight expenses? Are there limitations in warehouse space to consider?

- Supplier performance – what is the lead time for goods being replenished? When will purchase orders need to be placed in order to meet future demand?

- Relative product importance – a high-value product with high sales demand, for example, might require a conservative demand planning approach, as stocking out would have a serious impact on revenue.

Learn more: Supply Chain Planning Guide.

Why is demand forecasting important?

Demand forecasting is a critical component for many businesses, so let’s focus on some of the fundamentals that provide value. SMEs are facing longer lead times and unpredictable supply chains. In the UK alone, lead times jumped from 15 to 27 days, a clear signal that businesses need to plan further ahead to avoid stockouts or delays.

Here are the major benefits of demand forecasting:

1. Meet customer expectations

When you have accurate demand forecasting, you will have the products your customers want, when your customers want them. Problems arise when you don't have the right amount of inventory to meet demand. Customers get frustrated, and you risk losing them if you cannot provide the product.

2. Demand forecasts improve profitability

An unplanned stockout ahead of a peak sales period can be a disaster at worst – and at best, a major lost opportunity. Being able to accurately forecast demand allows you to maximise your return on inventory investment by ensuring you have enough stock to service future sales. Failure to do so represents an invisible cost to the business as potential revenue goes begging.

3. Awareness of future demand decreases the cost of inventory

Demand forecasting can also play a significant role in decreasing the amount of money spent on inventory. If the amount of inventory is accurately forecasted, then you only need to have enough inventory space and employees to manage it. Inventory costs can skyrocket when you have an excess of inventory stock - whether you run your own warehouse or work with 3PLs.

4. Minimise safety stock

Accurate demand forecasting can help you to prevent resource wastage, such as obsolete or excess safety stock. Excess stock can accumulate when inventory is ordered but not sold, for whatever reason, leading to financial wastage. By forecasting demand accurately, you mitigate the risk of ordering large amounts of unpopular products which have lost favour with your customer base.

5. Using historical sales data helps you repeat past success

By looking at historical sales data and trends as part of a comprehensive demand forecasting plan, inventory managers can look at what has worked in the past and repeat it where appropriate. For instance, you may find that the previous summer sale brought in a lot of new customers. You can use this information to repeat the sale in the future.

6. Demand forecasting improves cash flow

Accurate demand forecasting can have a dramatic impact on your use of working capital and the preservation of your cash flow. Having money tied up in excess stock can stress your company's ability to make debt repayments and inhibit your investments in growth and development.

Demand planning example

Demand forecasting is relied on for some of the biggest predictions globally, thanks to its advanced capabilities through machine learning. AI can now assess factors including economic conditions and consumer behaviours, increasing the accuracy of predictions.

Demand forecasting methods

Clearly, effective demand forecasting can be complex: it deals with the uncertainties of future demand, historical data, variabilities within the supply chain, and both quantitative and qualitative data. To manage these different factors, a variety of demand forecasting methods are used:

Qualitative demand forecasting methods

Qualitative methods of demand forecasting include 'the human element' by surveying experts and/or the wider marketplace for their input. Building a model of future demand in this way can involve market research, input from your sales and marketing teams, or even simply the views of those closest to the business. Formal frameworks for creating this demand forecast include the Delphi Method and the panel consensus approach.

Quantitative demand forecasting methods

Data-based demand forecasting models can blend historical data with other factors – such as the number of promotions run for a product – to create more or less complex demand forecasts. These types of demand forecasting include simple linear regression analysis, multiple linear regression, and causal demand forecasting models that combine historical data with multiple real-world elements known to influence future demand. Finally, predictive big data analytics is increasingly being used to forecast demand. These types of demand forecasting may even include inputs that those seeking to predict demand are unaware of.

Demand forecasting software

While the science of building demand forecasts is fascinating, typical supply chain managers at small-to-medium businesses often need a more practical approach, and turn to demand forecasting software to answer several simple questions:

- Do I have enough stock to meet future customer demand?

- Are demand trends dropping, stable or rising for particular products?

- Do I have sales forecasts for my highest-earning products?

- Have I accounted for seasonal demand?

Advanced Inventory Manager is a popular supply chain management tool that concentrates on this practical approach to inventory planning. Part of the Unleashed inventory management system, it combines past sales data with qualitative inputs to build demand forecasts that can quickly be turned into real-world inventory planning strategies.

Demand forecasting examples

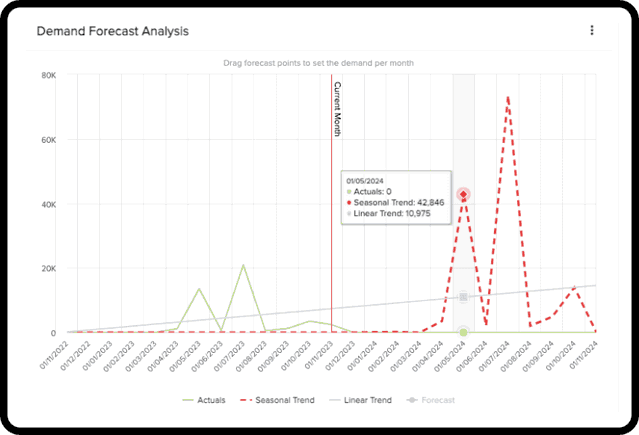

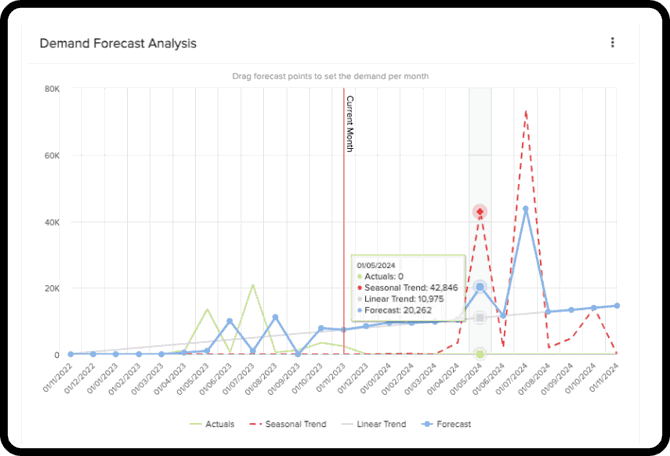

Here we can see demand forecasting software (Advanced Inventory Manager) being used to project future demand for a product – in this case, a six-pack of lager manufactured by a brewery – with the forecast then being used to set an inventory management strategy that ensures inventory levels are sufficient for future sales. First, the software (AIM) uses past sales data to plot a simple linear trend projection of customer demand (the grey line), which in this case shows rising customer demand. Meanwhile, a seasonal demand analysis (the red line) is predicting two distinct peaks in demand growth.

This combination of trend and seasonal forecasting reflects two core demand planning methods: time-series analysis and seasonal modelling. Together, they form a robust demand forecasting model that helps businesses anticipate fluctuations and plan accordingly.

Next, the user inputs their own demand forecast (the blue line), potentially calling on market research, external sales data, advice from marketing teams, their own knowledge of industry trends, and other qualitative methods to predict demand.

This blend of quantitative and qualitative forecasting is a hallmark of effective demand planning, allowing businesses to adjust for real-world variables that pure data models may overlook.

Next steps: Inventory planning

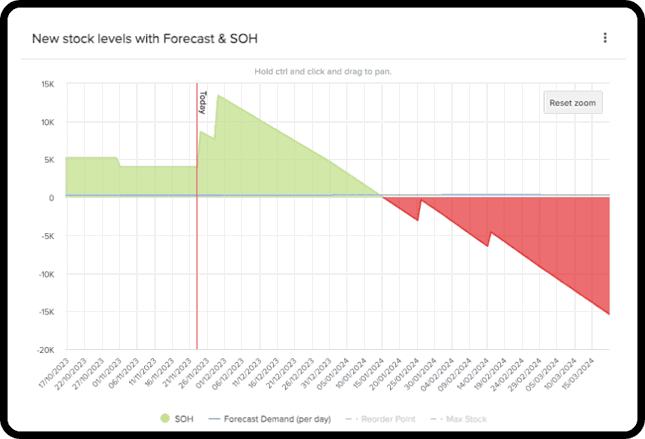

Having achieved a general consensus on forecast accuracy, demand forecasters toggle to a burn-down chart to check inventory levels against the trend projection. It's worth noting that perfectly accurate demand forecasts are not always required here: the goal instead is to manage inventory within acceptable boundaries, avoiding stockouts at peak periods.

This step demonstrates how demand planning models are used not just to predict demand, but to inform tactical decisions around stock levels, reorder points, and supplier timing.

Instantly, this burn-down view of inventory levels for the product (green) reveals that the forecast future demand will erode stock to zero (red) just as sales data predicts customer demands for the beer will be peaking. So, while the forecast accuracy is open to debate, these practical types of demand forecasting can suggest when prompt action is warranted: in this case, purchasing enough product to match sales projections.

This is a clear example of demand planning in action, where forecast insights are translated into operational decisions that protect revenue and customer satisfaction.

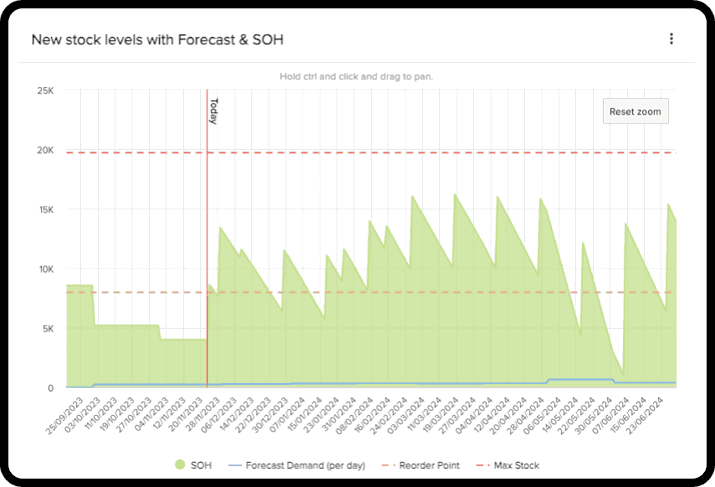

Supply chain planning in action: deploying a strategy

The final step in the process is to adjust the reorder point and maximum stock level controls for the beer product until the stockout risk is under control. Here, the burn-down chart shows a much more normal series of peaks in stock on hand – as orders arrive in the warehouse, followed by dips, as sales eat away at inventory. With a click, these inventory controls – the new minimum and maximum inventory levels – are submitted into the reordering system, so that purchase orders can be raised at the right times – and for the right quantities – to meet demand.

This illustrates how demand planning methods integrate with supply chain systems to automate replenishment and maintain optimal inventory levels. By aligning demand forecasting models with inventory controls, businesses can reduce waste, improve cash flow, and respond dynamically to changing market conditions.

Demand forecasting best practices

Once the inputs we mentioned earlier are available, in order to effectively maximise your demand forecasting system results, follow these three key practices.

Include customers in your analysis.

By factoring customer planning and forecasting information, you can reduce forecast errors and have a more predictable demand model. Best industry practices use monthly or weekly inputs regarding customer inventory planning and getting advance notice of promotions.

Ask suppliers

Speaking to manufacturers and suppliers can be an overlooked form of market research. Often, they will have knowledge about products that can improve your insights. New product information, in particular, can be valuable as you build your demand forecast – for example, a new product launch from a supplier may affect demand for a similar or older product and alter your trend projection.

Apply demand sensing & shaping techniques.

This approach examines demand from a more holistic view, grouping items into segments with common demand requirements. For example, a confectionery manufacturer would apply the same seasonal consumer trends to a common demand forecast for their ice cream product category. This shaping process can influence downstream supply chain activities and help balance your inventory stock for the best ROI.

6 highly useful demand forecasting tips

When many businesses forecast demand, even the most studious companies will not get it 100% accurate. Instead of perfection, the focus should be on minimising errors. Here are some tips to help you get it right.

1. Strike a balance

Find the equilibrium between statistical modelling and collaborative forecasting. Using both of these methods helps improve accountability for the business's ability to forecast demand more accurately and enables continuous improvement across the company.

2. Don't just focus on historical data

Historical demand data is useful for establishing a baseline for forecasting future demand. However, historical data is not always the best indicator of a company's final demand. If you only consider what happened the previous year and neglect everything that is taking place in the current market, your demand forecast will be incomplete.

3. Identify significant factors and adapt

There are many factors, such as economic, social, climate, and political changes, that can affect your demand forecast. These factors could be circumstantial or a more profound trend change. Your business's ability to adapt to change will help you stay competitive.

4. Measure forecast accuracy at different levels

Demand forecasting may be undertaken at three different levels: the item, location and customer level. Customer or sales forecast accuracy should be measured for continuous improvement and accountability. The appropriate place to measure for continuous improvement is in the sales and operations planning review process.

5. Account for lead times

As customer demand is at its highest point during the year in a business's peak season, ensuring lead times are well accounted for is a no-brainer. However, it is important to note that if you have suppliers in other parts of the world, you may need to factor in lead times that have their own seasonality – for example, cultural events like the Chinese New Year and Diwali, or summer holiday shutdown periods in Europe and Australasia – that can have economic implications for the supply chain.

6. Monitor economic drivers

Economic drivers represent all the forces that generate opportunities or costs for your business. For better demand forecast accuracy, economic drivers need to be taken into account that look beyond just what will affect demand. Take, for example, when considering two products with the same expected future demand, the final purchase order decision can be very different if one product is expected to be long-lasting, while the other is perishable – the demand levels might be equal, but the respective inventory risks aren't.

Expert panel discussion: Getting demand forecasting right

While forecasting demand is a complex – and sometimes inexact – science, the consequences of getting it wrong (or simply not doing it at all) can be severe. Unleashed gathered five supply chain management experts to discuss how crucial forecasting demand is for mitigating risk, and how businesses can create more accurate forecasts.

- Access more expert discussions by subscribing to Stock, Collaborate, and Listen - the Supply Chain Management podcast from Unleashed

Ready to put your demand planning into action?

Unleashed’s Advanced Inventory Manager (AIM) helps you turn demand forecasts into real-world inventory strategies. Whether you're using seasonal trends, regression models or collaborative inputs, AIM gives you the tools to optimise stock levels, reduce risk, and respond to demand with confidence.

Start your 14-day free trial and see what Unleashed can do for you.

Frequently Asked Questions

What are the five types of demand forecasting?

The five main types of demand forecasting methods include:

- Delphi Technique – A qualitative method using expert surveys and feedback rounds to reach consensus.

- Regression Analysis – A causal method that examines relationships between demand and variables like price or advertising.

- Machine Learning Forecasting – Uses algorithms to analyse complex datasets and predict demand, ideal for volatile markets.

- Simple Linear Regression – A quantitative method that projects future demand based on historical trends.

- Predictive Big Data Analytics – Combines historical and external data to forecast demand, often revealing hidden influencing factors.

How do you calculate a demand forecast?

Demand forecasts are calculated by combining historical sales data with influencing factors such as seasonal trends, supplier performance, and market research. Techniques range from simple linear regression to machine learning models. Tools like Unleashed’s Advanced Inventory Manager allow users to input their own forecasts and compare them against algorithmic projections to guide inventory planning.

What is the KPI for forecast accuracy?

Forecast accuracy is typically measured at three levels: item, location, and customer. The key performance indicator (KPI) is the percentage accuracy of predicted demand versus actual sales. This is reviewed during the sales and operations planning process to drive continuous improvement and accountability.

Next chapters

Check our blog for more news and tips on inventory management and demand forecasting.

Read blog