Unleashed team are always available and…

Unleashed team are always available and quick to help. Tailor their approach to match the customers learning speed / uptake.

Whether it’s your first inventory platform or an upgrade, you’ll unlock all-new levels of productivity with Unleashed’s inventory management features

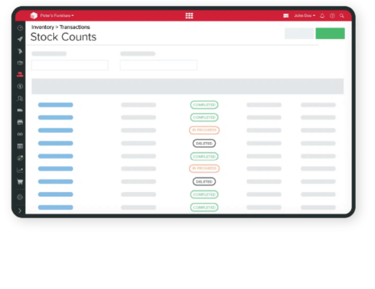

Unleashed is a perpetual inventory management system that reflects your stock position in real time.

All your stock movements are updated as they happen – whether that’s goods coming in or out of your business, moving between locations, or being used up in production – so you always know what stock you have, and where it is.

Unleashed’s Advanced Inventory Manager (AIM) module auto-detects an optimal min-max level for every item in your business on the go, based on your own unique lead times and rate of use. AIM lets you set custom levels for different locations – keeping your stock in a healthy range and saving you thousands – while powerful inventory planning software features, including a full inventory forecasting system, help you model your future needs.

#1 IN CUSTOMER SUPPORT

Enjoy round-the-clock support from the top-rate customer support in the industry with email, phone and live chat options to suit every business.

Learn more about Unleashed’s inventory control software features in the pages below

Real-time inventory means knowing exactly how many products you have in stock at any moment. It involves continuously tracking product movements to control stock levels and meet customer demand. Companies often use software with real-time tracking functionality to avoid stockouts throughout the supply chain and inventory management lifecycles.

Based on a comparison of 70+ brands on Capterra, the average cost of an inventory management system is USD$175 per user license, per month. Unleashed is significantly more affordable, with monthly user licenses priced at USD$88 per month on its most common plan.

Other costs for inventory management software include customer support fees, which are often billed separately. Expect to pay around USD$80 per month for a support package.

Explore inventory management software costs in our guide to The average cost of an inventory management system or jump straight to the Unleashed pricing page.

Inventory management software works by creating a ‘digital twin’ of a company’s real-world inventory – as well as records for sales, purchases and any manufacturing.

This live inventory tracking largely removes the need for stocktaking. For example when new stock is purchased and arrives at the warehouse a barcode scanner is used to record its arrival, with the inventory management software system updating the stock count for those products – along with details such as the stock’s location, purchase price & any additional variable costs such as transport fees, the date of its arrival and even its physical dimensions.

Equally, when a sale is made this process runs in reverse, with the stock count for the items sold being reduced and further details such as sale prices captured.

Finally, if stock is used in a manufacturing process inventory management software will reduce the stock held for all the components or ingredients as these are consumed, and increase the stock count of the new product being created.

Inventory management software will also update accounting records in real time, allowing for much more accurate financial management in companies that buy and sell physical goods.

For an in-depth explanation of all things inventory management see the Unleashed Inventory Management Guide.

Inventory management software lets businesses keep stockholding costs to a minimum by matching their demand to the level of inventory held for every different part or product across multiple warehouses – while simultaneously maintaining high customer service levels by preventing stock outs.

It does this by automatically prompting users to created and send purchase orders when stock levels drop to a specific ‘reorder point’ or minimum stock level.

Other key tasks for inventory management software include:

For an in-depth explanation of what inventory management software does, see the Unleashed Guide to Inventory Management Systems.

There are multiple ways to do this. One way is to use the Unleashed stock-on-hand enquiry report. You can also use an item inquiry report to gain an understanding of stock availability data. Stock can be reserved for a sales order or a manufacturing process – and Unleashed gives you the necessary insight into how much stock is available.

We use the average landed costs methodology only. This methodology is at the heart of Unleashed’s perpetual inventory management system. Obviously you are free to use FIFO/LIFO principles in terms of physical stock movement (but not when costing).

Yes, you can use warehouse transfers to transfer stock between multiple locations. You can also do a manual stock adjustment to maintain stock counts if stock is written off. Furthermore, Unleashed’s stock-on-hand (SOH) report allows you to understand how much stock is available for a particular product in all locations. This is perfect for customer enquiries to ensure you don’t miss out on a sale if the stock actually available, yet in a different location.

As soon as you start holding stock you need to have batch and serial numbers associated with this stock (if applicable). It depends how products are brought into Unleashed. If you are bringing stock in through a purchase order, serial and batch numbers must be added at the time of receipt. If you are doing an adjustment, you need to add a batch or serial number when you are completing the adjustment. If you are doing a credit, then you need to advise what you are bringing in via the credit. Note: Using batch or serial tracking for each product is not mandatory.

Yes, you can see a full transaction history of when the serial and batches were created, when the product(s) were actually sold, used, or deleted.